Our Business Activity

At Organics2Power (O2P), everything revolves around the idea of how to wisely and safely collect and reuse organic materials and prevent them from simple incineration or going to landfill.

SecAnim, which is short for Security in Animal Processing, is our specialist for collecting and processing fallen animals and potential risk material from the meat and livestock industry according to the highest safety standards. They serve as precious input materials for the production of green energies and fertilizers.

At ReFood, we target different sectors by collecting leftover food, organic residues from food-production, and used frying fats from industries as diverse as food production, restaurants, and retail. Through carefully coordinated processes, we prevent food waste and ensure optimal valorization by deriving sustainable energy in the form of green electricity, biogas, and heat, as well as input materials for biofuels from these materials. Thanks to our holistic approach, we are also able to reuse the by-products of our biogas plants as organic fertilizer. “Within the EU Farm to Fork Strategy, transforming food waste into feed is part of the European Commission’s action plan against food waste, and a sustainable competitive differentiation from other compost or biogas companies. Furthermore, sorting food waste raises awareness among companies and our society, helping to prevent food loss and waste along the food production and supply chains.” (Roberto Perez, O2P Sustainability Director)

Always striving to connect the dots within our divisions; this is where ecoMotion comes into play. It is supplied largely by SecAnim and ReFood to produce high-quality biodiesel, which it has been producing and selling since 2001. With a history of more than 20 years, we are not only a pioneer in the biodiesel industry. Today, we are also one of the leading suppliers across Europe for biodiesel produced from residues, and a pioneer in the development of sustainable aviation fuel (SAF).

Our Sustainability Strategy

We consider our long-standing commitment to reuse precious organic materials in innovative ways not only as a sustainable business advantage, but also as a responsibility to make a meaningful contribution to sustainable development, including the reduction of food waste. This is why we actively support the United Nations Sustainable Development Goals (SDG’s), which we regard as the preeminent global framework for social, environmental, and economic progress. Based on our encompassing materiality assessment, we have identified 11 focus goals for O2P to which we seek to contribute.

At O2P, we believe that strategic decisions can best be made when they are grounded in reliable data. For that reason, we have established a sustainability dashboard containing four key performance indicators (KPIs) that reflect sustainability areas of crucial importance to us. They are reported on a monthly or quarterly basis and help us measure our sustainability performance and assess the effectiveness and efficiency of our actions. Moreover, the data is provided both at site and business unit level, which allows us to take precisely targeted actions for improvement. Systematically determining the areas of relevance to us and to our stakeholders was a decisive step in our strategy development.

Our different business activities actively contribute to the United Nations Sustainable Development Goals.

Our Sustainability Organization

Materiality Assessment

To identify material sustainability topics for our division and its three business units – SecAnim, ReFood, and ecoMotion – we introduced four measures to include different perspectives and a wide range of expertise.

Preliminary guidance for us was provided by the latest SARIA Group Materiality Assessment, focusing on the O2P-related data. In a second step, we followed up with sustainability strategy workshops at SecAnim and ReFood, which were conducted by an external consulting company.

This effort was complemented by two more activities: first, a sustainability survey distributed among important O2P stakeholders that we had previously identified; second, a strategy workshop with our sustainability team, including our Sustainability Director and our sustainability Task Force, which is made up of six people from Smart Technologies (Health and Safety, Quality and Operational Environment), Communication, Finance, research and Development, and IT.

Sustainability Meeting with participants from Spain, France, and Poland

Our Material Topics – Selected Activities and Accomplishments

At O2P, good governance is our moral and legal foundation. Acting sustainably and in compliance with laws and regulations is non-negotiable. Despite this conviction being deeply rooted in our organization, we do not regard legitimate and sustainable behavior as something automatic. We work hard to ensure it day by day.

Sensitizing and training our employees on all relevant matters is thus essential to our approach. Our managers in charge of the respective topics meet with our CEO on a monthly or bimonthly basis to discuss important issues related to sustainability. Moreover, every month we communicate a specific sustainability topic through the intranet to our employees, using interviews, articles, and infographics to illustrate the content and make it easily applicable.

To reach the next cognitive level, we aim to provide online training sessions to all employees, covering our material topics. For our board and our managers, the sustainability team regularly prepares information so as to equip them with the necessary in-depth knowledge and information. Furthermore, a training and communication program is being set up to address and increase sustainability awareness throughout the entire O2P organization.

To support our people with modern IT solutions, we are progressively introducing a state-of-the art compliance tool that allows us to systematically measure and monitor our performance in crucial areas of compliance:

- Environmental protection

- Industrial safety

- Health and safety

- Product and quality assurance

- Logistics

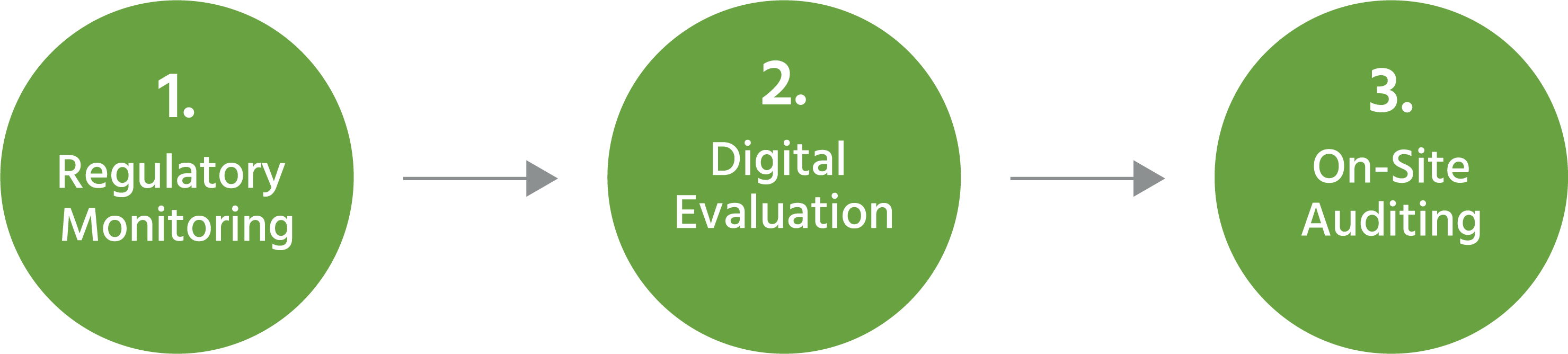

The tool is process-oriented and contains three major consecutive elements.

All our processes comply with extensive regulatory requirements to ensure safe and hygienic disposal of potential risk materials.

SAF project between SARIA and TotalEnergies: Statement by Nicolas Rottmann

The first step consists of the systematic capture of legal and regulatory requirements, in particular new ones. The platform also displays all relevant key performance indicators and can be switched to different languages to ensure easy use across all locations. In addition, there is an integrated hotline in case of questions. In a second step, the uploaded performance data is matched against the respective requirements and assessed for conformity. Finally, there is the option of on-site auditing as a follow-up, which we recommend on a yearly basis for each of the production sites, and every three years for our logistics and administrative centers.

All across our division, innovation is a key driver of our business success. We are constantly seeking to develop new products and services to promote sustainable development. Against the background of the discussion on energy supply self-sufficiency that has intensified after the war in the Ukraine, we are proud of having initiated a landmark project together with French multi-energy group TotalEnergies.

In collaboration with this renowned partner, we will produce sustainable aviation fuels (SAF) on the Grandpuits (Seine-et-Marne, France) zero-crude platform. The agreement we entered into in September 2022 is a major step in securing feedstock supply (used cooking oils and animal fats) eligible to produce SAF. The related production capacity will reach 210,000 tons per year in addition to HVO, LPG, and bio naphtha.

As this example shows, our business activity is strongly influenced by political initiatives and regulation. This is why it is part of our innovation processes to anticipate new regulatory conditions and to prepare for changes on the horizon at an early stage. In Denmark, for example, it became an industry requirement in 2023 that pick-up places for deceased pigs are covered. This is why our people at Daka SecAnim have updated the guidelines on pick-up points at individual farms in collaboration with the Danish Agriculture & Food Council Pig Sector. The guidelines ensure that the collection points cause the least possible nuisance to the surroundings, meet requirements to minimize the risk of spreading infection, and ensure good-quality raw materials for the recycling process.

Since complying with new regulations can be challenging, we are also seeking to support our partners in meeting new requirements. At Daka ReFood, we are helping Danish companies to prepare for the New Waste Consolidation Order, which entered into force in January 2023 and requires companies to sort their waste as private households do by separating it into 10 different types. Katja Juul Nielsen, marketing manager at ReFood, explains potential difficulties and the support ReFood can offer: “The challenge is the time it takes to familiarize yourself with the new rules and the implementation of the solutions that fit the needs of the company. The Danish Environmental Protection Agency has prepared some material on waste sorting that you can use as a starting point. However, for many companies, it may be easier to let a professional business help you find the optimal solution. Companies, like us at ReFood, can offer support regarding operational issues, but also with managing documentation requirements, which can be particularly complex to get to grips with.”

The pick-up area for deceased pigs is often the outside world‘s first encounter with the individual farm, as it is close to public roads, so the truck can easily collect the pigs. That is why it is so important that the space is discreet and hygienic', says Søren Mohr Jensen from Daka.

Gas leakage simulation at Les Herbiers, France

In many cases, regulatory changes are driven by changing attitudes in society. More and more people are becoming aware of the importance of protecting valuable resources, even though they might not seem to be of value at first sight. At ReFood Germany, we support private initiatives and have started to collect waste fat from private households, which we use to create alternative energies.

The regulatory environment is also of utmost importance when it comes to the health and safety of our employees. At all of our locations, we make sure to comply with existing regulations to guarantee that our people can work under safe and healthy conditions. To even exceed what is expected from us in regulatory terms, we currently develop a division-wide safety policy that we will launch in 2023. Regular sustainability reporting contains a dedicated section on Health and Safety with related KPIs measured at each site.

Like in other areas, our approach is characterized by collaboration and partnership. This is why we continuously intensify the work with local fire brigades. At our anaerobic digestion site in Les Herbiers, France, we held a full-scale emergency drill, simulating a gas leak in the cogeneration engine sector. By doing so, we provided the firefighters with better knowledge of our plant, products, processes, and related risks and made sure that the designed safety measures and procedures are carried out accordingly. All of these measures contribute to the safety of the firefighters, our employees, and the people in the neighborhood in the event of an incident.

In Poland, SecAnim and ReFood support the Volunteer Fire Brigade in Czempiń. In 2022, they donated a PSP R1 professional paramedic kit that can also be carried as a backpack and thus be easily transported to accident sites that cannot be reached with heavy gear. The rich equipment of the set is tailored to treat various injuries, which makes it useful under varying conditions.

Combating climate change is another issue that we have identified as material. Across all of our locations, we are taking initiatives to reduce our carbon footprint through various measures.

Switching to alternative power is one key undertaking in this regard. At our ecoMotion production site in Montmeló, Spain, we have installed almost 600 m2 of photovoltaic panels that generate 132 kWp on average. At ReFood, we have finalized planning for the generation of 160kWp through panels on roofs of different factory sites and the headquarter parking lot in Selm, Germany. Since its construction back in 2009, the digestate storage at the ReFood site located in Les Herbiers, France, is covered with 1800 m² of solar panels.

Support of the Volunteer Fire Brigade in Czempiń, Poland

Installation of photovoltaic panels at the ecoMotion production site in Montmeló, Spain

While switching to renewable energies, we are making considerable efforts to reduce our usage of fossil fuels and related emissions. Our SecAnim engineers in Plouvara, France, where we process animal by-products in large cookers, have developed a concept, where one of the cookers will be replaced by an evaporator that relies on waste heat generated in our industrial processes. At Malchin, Germany, we have installed two highly-efficient duobloc burners for vapor generation that save approx. 2,000,000 kWh per year. To the south of Malchin, at Genthin, ReFood produces biomethane and uses it as biofuel, which reduces GHG emissions by 90% compared to traditional fuels.

Aside from manufacturing itself, we are also modernizing our vehicle fleet. In Germany, 63 old trucks were replaced in 2022 by new models that meet the strictest emission standards. To accomplish the switch to renewable alternatives here in the long run, we have been experimenting with CNG-, LNG- and e-Trucks since 2019. And we are cutting emissions by increasing operational efficiency. At SecAnim in Germany, dynamic logistics reporting was established to optimize freight routes and matching vehicle use.

Reducing input and finding innovative ways of recovery is our approach too when it comes to water management. At our SecAnim production sites in France and Spain, 60% of our water consumption comes from water reused thanks to the fact that water makes up close to 70% of our raw material; after this reusage, we manage to return 60% of it back to nature in purified form.

At our facilities in Termens and Segovia, Spain, our waste water undergoes a four-step recycling process. In a first step, chemical treatment is applied to physically clean the water, before its quality is improved further through biological treatment. To take out remaining unwanted particles, the water is filtrated in an extremely granular process. The final osmosis leads to a degree of purification, which allows the water to be returned to the river even under the strictest environmental standards. Thanks to that, in France and Spain we reused close to 200 million liters during 2022.

In many of our production sites, we operate on the basis of management systems certified in accordance with globally recognized quality standards.

Water Cycle at our SecAnim sites in France and Spain

Spotlight on School and University Collaboration

At O2P, we regard it as our responsibility to engage with students of all ages and contribute to SDG 4 (Quality Education) – also outside of our business. For example, our employees are giving courses at agricultural schools and universities on a large diversity of subjects such as the sustainable reuse of by-products, traceability and management control on farms, and effective biosecurity measures at animal collection points.

Agricultural schools are also supported by our people at ReFood. At L’IRÉO in Les Herbiers, France, they are engaged in a specialization certificate on safety and security at agricultural biogas plants. In Parthenay, France, we collaborate with the Lycée Général et Technologique Ernest Pérochon to give students the possibility to work on waste biodegradability. This creates a win-win situation as students get practical experience during their “Science and Laboratory Courses” and gain a deeper understanding of biowaste treatment, while we can attract the workforce of the future.

We believe that educating the next generation about food waste and its place in the food chain has never been more critical. At ReFood UK, we have developed a series of lesson plans to inspire and educate pupils on the benefits of recycling, which can be downloaded for free on our website. This information package contains all relevant materials such as introductory facts and figures, a short explanatory film, as well as various download materials to be used in the different lessons.

Technical Agriculture Engineering training

Looking Ahead

At O2P, we want to use our innovative strength and dedication to further extend our contribution to sustainable development. In collaboration with our stakeholders, we are working on solutions to increase the social, environmental, and economic value we create through our business with this approach.

We are convinced that there is no trade-off between economic success on one side and social and environmental responsibility on the other side. We do not even like the perception of two sides in this regard, because to us it is all one. And we have demonstrated since the inception of our companies that progressive environmental solutions can be the foundation for sound business and value.

Against the background of grave environmental challenges, we are aware that the industries we are involved in will undergo substantial changes. But we do not regard that as a threat. We have always seen challenges as a window of opportunity – no matter if they are regulatory, technical, political, or social in nature. Allow us to provide a small, but characteristic example of how our people approach new developments through their entrepreneurial spirit.

In 2023, French legislation regarding biowaste will change and require producers of more than five tons of biowaste per year (previously ten tons) to develop solutions for recycling their biowaste. Unsurprisingly, tightening regulation such as this is perceived as a nuisance or even a threat by many stakeholders. Due to the reduction in quantity, many restaurants will become subject to the new law. We are convinced that we can create a win-win or even win-win-win situation in cases like these. Our people at ReFood will actively get in touch with restaurant owners to discuss collaboration on biowaste collection and help them deal with tightening regulation. Their leftovers in turn is the source of our business, and through carefully reusing it, the environment also benefits as precious materials are kept in the cycle.