Our Business Activity

Sinova is one of the leading manufacturers of sustainable ingredients for the petfood, aquafeed and feed industries as well as for oleochemical and renewable energy markets worldwide. We contribute to the circular economy by processing raw materials of animal origin, which we use to supply our industrial partners with a wide range of valuable input materials. At all our locations, we want to play our part in making the most out of the Earth’s limited resources.

Our goal is to provide our customers with the raw materials they want and need, in the quality they expect to receive them. We achieve this by reusing what would otherwise go to waste. By doing so, we not only help to avoid the incineration of precious materials and resulting CO2 emissions. We contribute to the protection of biodiversity, as our products reduce the need for additional farming and fishing.

As a family-owned business, people are at the heart of our organization. Together as ONE team with an agile organizational structure and a modern leadership approach, we develop and deliver best-in-class solutions in collaboration with our internal and external partners along the value chain.

Using resources wisely and with a long-term perspective, also applies to how we do business financially. We are convinced that financial stability is the foundation for lasting success. Most of our profits are reinvested in the continuous development of our industrial network and service performance for our customers. Since we want to be as close to them as possible, we act locally in the upstream and globally in the downstream value chain. By doing so, we are able to best meet their needs, create innovation jointly and operate our supply chain in an efficient and sustainable way.

Our Sustainability Strategy

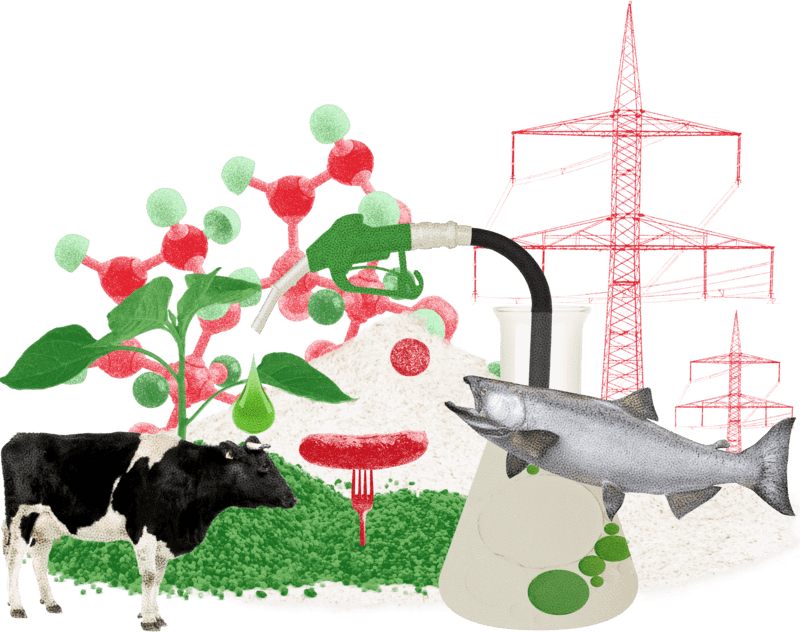

At Sinova, we convert animal by-products from the meat and fish industry into low-carbon materials for re-use in production processes and other applications in a broad range of industries. Our approach is to create value by delivering the products that our customers want, innovating together with them as a partner. We work with a great variety of supply chain partners to enhance the sustainability of the international feed value chain and safeguard the health and welfare of animals. By doing so, we actively contribute to a circular bioeconomy, in which renewable biological resources are produced and converted into value-added products, such as feed, bio-based products and bioenergy.

The low carbon footprint of products derived from animal by-products in turn helps to decarbonize the value chain by substituting higher-impact primary resources such as imported vegetable-based feed ingredients like palm oil and soya, chemical-based fertilizers and fossil fuels.

Having sustainability at the heart of the business is a great starting point to help us drive the transition towards a low-carbon and circular future, but we do not rest on that. We have also devised our sustainability strategy to address important social and environmental issues and derive effective actions.

A Circular Bioeconomy

Our Sustainability Organization

Materiality Assessment

In order to include sustainability issues at the heart of our strategy, we have carried out extensive mapping work according to the ISO 26000 standard, the guideline for corporate social responsibility.

To complete our assessment, we analyzed important external developments and identified three major challenges:

-

The race to cut down greenhouse gases

The stakeholders along our value chain are striving to reduce their emissions at high speed. Our customers on one side are looking for products with the lowest carbon footprint, attempting to reduce their scope 3 emissions. On the other side, our raw material suppliers are also turning to us looking for solutions as we deal with their by-products. -

The depletion of natural resources

Climate change is already causing water shortages in many regions, which is a threat to our water-based production process. Likewise, the depletion of fossil fuels and their carbon intensity makes the search for alternative solutions a necessity. -

The future of the meat industry

A growing number of end consumers are turning away from meat and meat-based proteins, searching for potential alternatives. Due to the corresponding decline in meat consumption, we might face a shortage of the input materials we require while demand for our products is increasing.

Based on this, four material topics for Sinova were identified:

- People management

- CO2 reduction

- Environmental management

- Sustainability in the value chain

To increase sustainability in the value chain, our primary goal is to further expand collaboration with our partners to increase transparency and joint innovation development. Regarding the reduction of CO2 emissions, we want to use renewable sources of energy in our facilities. This also contributes to our third overriding goal – energy and water independence. To achieve this, we will enhance our environmental management, while also continuing to reduce our environmental footprint. None of this can be achieved without the well-being and development of our people. Their health and safety and the establishment of a diverse workforce is our fourth major goal.

Material Topics for Sinova

Our Material Topics – Selected Activities and Accomplishments

At Sinova, we are convinced that the major challenges of the 21st century can only be addressed successfully through collaboration in the value chain. Since we are a major player in the circular bioeconomy, we are in a fantastic position to work alongside our supply chain partners.

This is for example what we do in Italy to enhance transparency in the supply chain: Our raw material purchasing department performs regular audits in all slaughterhouses from which we source materials. In 2021, we started to include sustainability issues in these audits. Potential topics include the reduction of CO2 emissions, use of alternative energies, reuse of process water, cogeneration plants and environmental certifications such as ISO 14001.

Generating reliable data along our value chain will help us to develop life cycle assessments for our products. It is our aim to be able to determine their impacts from the sourcing of raw materials to their usage. To further drive innovation in our organization, we have created the position of Chief Innovation Officer. In February 2022, Andrew Plews joined our leadership team and is steering our innovation strategy and the related activities. He has 15 years of international experience holding several senior management positions in Research and Development in the consumer goods industry, including Petfood. He is no stranger to the field and sees substantial possibilities connected to it: “Animal by-products offer great potential. I look forward to developing these potentials further and creating even more value together with our customers in the future.”

We produce a wide range of high-quality ingredients that are used in numerous applications such as animal feed, pet food, fertilisers, but also soap, paint and coatings or lubricants. To meet the high demands of our diverse customers, we are continuously working on improving the quality and safety of our products.

Energy Gemba Walk

One of his key tasks is to deepen our existing partnerships and create new ones. Together with eitFood and PoliHub, we are already collaborating to find suitable partners with forward-looking technologies and business approaches that promote digitalization and drive a more circular value chain.

When doing so, we actively cooperate with startups that work in the meat value chain with a fresh perspective. Our overriding goal here is to “make more out of less” by improving efficiency in the meat industry to get more meat from animals and make better use of the by-products.

One specific project that illustrates our efforts in this context is a project on feather digestibility. Feathers are a common by-product in the production process, and we seek to derive more protein from feathers, which leads to increased efficiency and recyclability.

When it comes to our climate protection efforts, calculating emissions is of primary importance. We have collected data on the energy consumption of all sites to calculate our scope 1, 2 and 3 emissions. Our calculations show that about 80% of our total carbon footprint results from scope 3 emissions due to the materials we use.

We regularly conduct so-called “Energy Gemba Walks” in our sites. “Gemba” is Japanese and means “the true place” – the place where things happen and where they can be changed. We conduct such diagnostics to collect ideas on how we can improve our energy management together with our colleagues who are in “the true place” and have the best understanding of what is feasible.

However, we know that meaningful climate protection also requires dedication from the top and discussions with customers. Through Peter Hill, the SARIA Executive Board member responsible for Sinova, we have committed to Science Based Targets driven by an initiative of the same name. It provides guidance on the quantity of emissions that needs to be reduced in order to limit global warming to 1.5 °C. In addition, it gives companies a science-based framework for defining ambitious and effective climate targets with a long-term goal of achieving net-zero emissions.

To start our journey, we have kicked off several renewable energy projects that not only reduce our carbon footprint, but also increase the energy security of our operations. In Poland, we have installed a photovoltaic system with a capacity of 50 kW. In France and Spain, we are planning several installations of photovoltaic systems that will be started in 2023.

Photovoltaic system in Poland

New preheater: As part of the “SARVAL goes green” project in Germany, raw material is now pre- heated by using waste heat, which reduces our primary thermal energy consumption and thus improves our carbon footprint.

At SARVAL Fischermanns, two projects on saving thermal energy at the German sites in Dissen and Hopfgarten were initiated. Savings are generated by using waste heat to preheat the raw material we use and dry the liquid in an evaporator. Savings amount to 36,500 MWh of thermal energy, leading to a reduction of more than 5,700 t of CO2 emissions. This innovative project is part of a holistic energy management, which is regularly certified against the ISO 50001 standard.

Successful climate and environmental management are inseparably linked. In 2022, we developed an encompassing sustainability dashboard to further monitor and improve our environmental sustainability performance. SINAPS (Sinova Analytic Platform & Solution) environmental dashboard was rolled out in early 2023 and comprises important indicators (e.g. carbon emissions and water consumption) for effectively reviewing and steering our environmental protection activities. The platform will be developed and adapted over time to meet our goals and ambitions. Our management as well as the functional units within our company, such as health and safety, logistics, finance, production and sales, will have quick and easy access to the information relevant for them – leading to faster, data-based decisions.

Pursuing a partnership approach, we are also introducing a new software tool together with SARIA’s O2P division to strengthen environmental regulatory compliance. This is of great help to our regional environmental managers to guarantee compliance with Directive 2008/1/EC on “Integrated Pollution Prevention and Control”.

A core aim of our people management is to ensure equal opportunities for all and to create a diverse organization. As one of our colleagues put it in our cultural diversity survey: “Promoting cultural differences within Sinova is a great opportunity for my personal development. Our cross-border meetings and participation in different transnational projects help us to exchange opinions and act like one team. They give me energy and make me proud to be a part of Sinova.”

Since diversity is a complex issue that entails many facets, we did not want to leave anything to chance. This is why we conducted a large study on cultural diversity in 2022 that is portrayed in our spotlight below.

Another essential element of our people management is a healthy and safe working environment. As part of a family-owned business, we not only see our employees’ safety as a legal requirement, but as our foremost priority and ethical responsibility.

”Seeing the process of changing people's awareness of health and safety always gives me an extra kick to keep doing my job.” Natalia Masiukiewicz – Regional H&S Manager Poland

International Health and Safety Meeting in Italy

One of our core aims is to make sure that our people enjoy safe working conditions at all of our sites. This is why we initiate regular cooperation among our regional and corporate health and safety (H&S) managers. In 2022, we held our International H&S Meeting in Italy, where all regional and central managers joined together for an exchange and site visits. They also participated in theoretical and practical training sessions on improving working conditions.

We have also introduced an interesting collaborative format among our regional H&S managers. We regularly conduct internal audits across countries at Sinova locations with constantly changing auditors. By doing so, we advance the transfer of knowledge and best practices, while efficiently detecting risks.

To ensure encompassing and reliable documentation as well as communication, all of our Health and Safety Managers have access to our H&S intranet, where they can find information on internal concepts and directives, project plans of all regions, accidents analyses, best practices as well as videos and pictures for accident education and awareness.

Since we also want to reach our employees directly, we undertake regular H&S campaigns at our locations. In Poland, for example, we started a large campaign to raise awareness for safety. Additionally, we conducted customized trainings on working at heights and in halls where raw materials are processed to prevent related accidents.

Spotlight on Diversity

Diversity is an important topic for Sinova, as we are acting in an international team with people from different cultural backgrounds and countries. We are in a change process to foster this internationality and use our diversity as an engagement driver not only for our employees, but also for our customers. We consider diversity as a strength to better address challenges from different perspectives, develop wider ranges of potential solutions and generate innovation.

To actively manage diversity at Sinova, we initiated a large online survey among our employees in 2022. As a starting point, we wanted to determine the status quo of cultural diversity in our organization and, more importantly, how our people perceive and feel about it. In addition, the survey was considered a good way to raise awareness for this topic and to actively engage our employees in the promotion of organizational diversity.

Overall, our findings were very positive:

- 95% feel motivated by working with colleagues from different countries

- 93% say that all cultural identities are respected at Sinova

- 91% think that our colleagues are open minded on diversity

Online Survey among our employees

Looking Ahead

A milestone in monitoring and reporting our sustainability performance will be reached in 2023, when we will complete the roll-out of our SINAPS dashboard.

Following our commitment to Science Based Targets, we will define specific targets in 2023 based on the analyses conducted for our scope 1, 2 and 3 emissions. Continuing our Energy Gemba Walks is also on our agenda for 2023. In the first quarter of the year, we have already conducted them at one site in Italy and three sites in Poland, where several opportunities for energy improvements were identified. Our goal for 2023 is to create and follow up on full action plans for the factories where we see the most improvement opportunities.

To further raise awareness of diversity among our leaders, we will conduct a special workshop format as a follow-up to our diversity survey. This is currently being tested and will then be rolled out within the organization.

At SARVAL in Germany, the gradual reduction of CO2 emissions and the use of primary energies in the operating processes is one of the most important goals. Various project ideas are therefore being examined at present, such as the use of waste heat from the steam boiler in Marl or the possibility of using micro steam turbines to generate electricity.